Smart Industry

Fourth industrial revolution is a fact. Industry leaders already learned how technology can help optimize manufacturing processes. This is happening around whole industry environment.

Machines at productions lines are acting with better precision and higher speed providing better manufacturing performance. Sensors are being deployed in various manufacturing floor locations providing data inputs to preventive maintenance, energy management, process optimisations. All advantages are easily demonstratable in business cases convincing manufacturing facilitators to make investment decisions. An opportunity for IoT systems integrators is significant – thus variety of available vendors and technologies make their live complicated. Softgent’s Flexgent solution helps to overcome IoT deployment complexity and beside delivering values associated with hassle free connectivity it provides platform for efficient and cost-effective device & connectivity management.

Data driven manufacturing optimizations

Manufacturers Holy Grail is to enable products to self-process, store data, communicate and integrate with larger industrial eco-system. This can be accomplished by engaging IoT sensors to measure operating conditions and efficiency. Efficiency measures not only apply to machines up times but also to manufacturing environment as well as data driven inventory optimisations etc.

Condition based maintenance

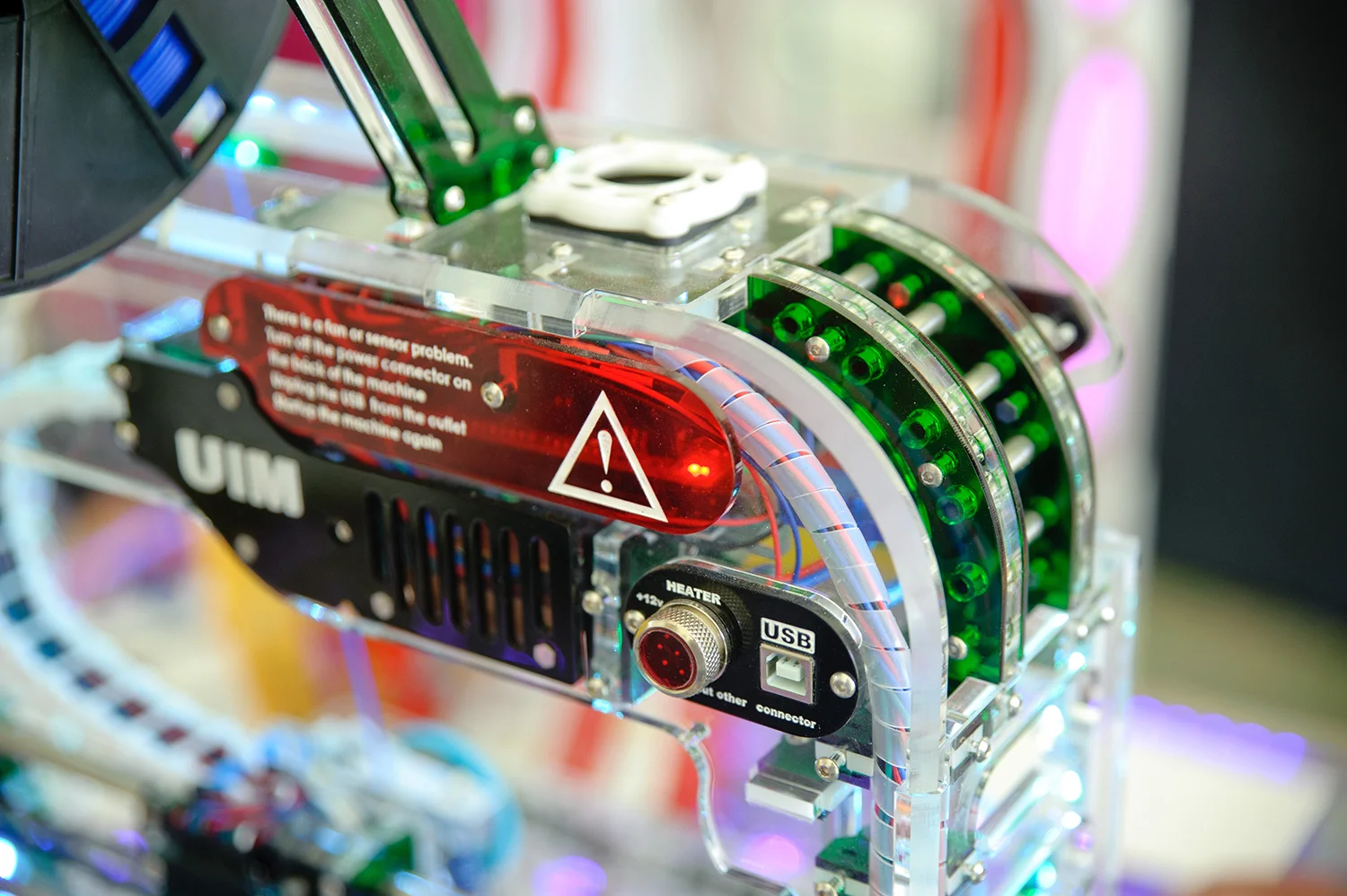

IoT sensors can be used as a source of data for condition-based maintenance providing indicators for service actions that could prevent future downtimes. Acquired data points can also be used for optimizing workforce schedules and perform equipment service on a need basis only.

read more

Nearshore Software development and testing

Nearshore Software development and testing READ DUTCH VERSION If there is one thing that Covid has convinced many of us,...

Read MoreNearshore Software ontwikkeling en testen

Nearshore Software ontwikkeling en testen Read english vesion Als er iets is waar Covid menigeen van heeft weten te overtuigen...

Read MoreWithout the Shield Box, 5G testing is out of the question

Without the Shield Box, 5G testing is out of the question — Niche technologies based on 5G are becoming increasingly common....

Read MoreLightweight IoT Platform

Lightweight IoT Platform Designed for Multi-Access EDGE Computing (MEC) — A typical approach of IoT platform vendors is to provide edge...

Read More