Transform Your Warehouse with IoT

Take Forklifts Under Control

Home > IoT - Flexgent > Transform Your Warehouse with IoT

Efficiency and safety are crucial in modern logistics and warehousing. Leveraging IoT, specifically Real-Time Location Systems (RTLS), can transform warehouse operations, especially forklift management. Integrating RTLS with environmental sensors boosts productivity, safety, and cost savings.

RTLS technology enables real-time tracking of forklifts, allowing managers to optimize routes, reduce traffic, and prevent accidents. Environmental sensors enhance this by monitoring conditions like temperature, humidity, and hazardous materials, enabling adjustments for optimal conditions for workers and goods.

Optimize Routings for Increased Efficiency

With RTLS, forklifts can be directed along the most efficient paths to their pick-up and drop-off locations, reducing travel time and increasing the number of loads moved per hour. For example, if RTLS data shows that certain aisles are congested, forklifts can be rerouted to less busy areas, potentially increasing productivity by up to 20%. This translates to an estimated dollar value of $50,000 in savings per year for a medium-sized warehouse based on reduced fuel costs and increased throughput.

Enhance Safety Through Collision Avoidance

By monitoring the precise location of forklifts, RTLS can help prevent collisions with other forklifts, employees or obstacles, significantly enhancing safety. Implementing collision avoidance systems can reduce workplace accidents by up to 30%, which not only saves lives but also reduces the potential for costly litigation and lost workdays. Assuming an average cost of $40,000 per accident (including medical bills, legal fees, and lost productivity), this reduction in accidents could save a warehouse operation upwards of $120,000 annually.

Apply Predictive Maintenance for Cost Efficiency

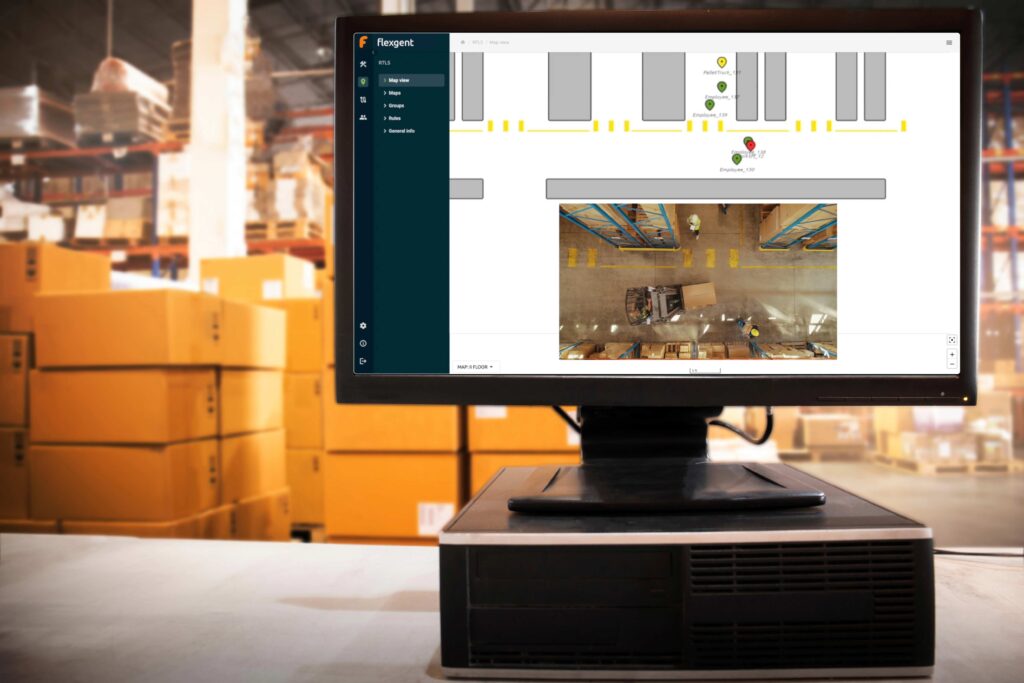

Revolutionize Warehouse Efficiency with FLEXGENT Platform

Our revolutionary UWB-based RTLS FLEXGENT offers a streamlined and efficient solution for advanced forklift management in warehouses. This system is centered around the innovative Flexgent sensor, designed for easy installation on the roof of any forklift. Powered either through the forklift’s power supply or by a durable battery capable of approximately two years of operation without replacement, the sensor ensures continuous, hassle-free monitoring.

To further enhance functionality and user experience, each forklift is equipped with a rugged tablet. This tablet is ideal for the demanding conditions of warehouse environments, displaying vital information such as the current and average speed of the forklift, its precise location, and various warnings, including potential collision alerts.

Beyond just real-time data, the forklift transmits detailed information to an analytical system. This system meticulously logs historical data, allowing for comprehensive analysis and insights into:

- Current and Average Speed: Ensuring operations are conducted safely and efficiently.

- Total Operating Hours: Essential for tracking usage and planning predictive maintenance schedules.

- Load Frequency: A measure of productivity, indicating the number of loads moved over a specified period.

- Route Efficiency: Provides data to optimize forklift pathways and workflow.

- Idle Time: Identifies potential operational bottlenecks or inefficiencies.

- Battery/Fuel Status and Usage: Critical for energy management and scheduling refueling or battery recharging.

- Accident/Incident Reports: Documentation and analysis of any safety incidents.

- Hours Since Last Maintenance: Helps in planning regular maintenance activities.

- Fault Codes and Alerts: For immediate attention to mechanical or software issues.

- Tire Wear and Pressure, Battery Health for Electric Forklifts, or Oil and Fluid Levels: Key indicators of vehicle condition, important for maintaining operational safety and efficiency.

The Trackgent system also provides customizable analytical tools such as Heatmaps and Spaghetti diagrams for visualizing forklift movements, as well as charts for daily usage/utilization, battery spillage, average speed, and more. These tools offer invaluable insights into optimizing warehouse operations.

Installation and configuration of the Trackgent system are straightforward and quick, designed to minimize downtime and disruption to warehouse activities. Despite its advanced capabilities, the cost of implementing Trackgent in a warehouse is remarkably low compared to the significant savings and improvements it delivers.

By enhancing operational efficiency, safety, and productivity, the return on investment becomes quickly apparent, making it a smart choice for any warehouse looking to leverage the power of IoT technology for forklift management.

Technology

Trackgent Anchor

Infrastructure for precise indoor positioning

Trackgent Tag

RTLS sensing device to be installed on each Forklift, measuring current location, time in move, average speed, route efficiency

PoE Switches

PoE (Power over Ethernet) switches are used to ensure reliable communication and support the necessary infrastructure for networked devices

Industrial Tablet

to provide support and vital information for the driver

Forklift Monitoring Sensors

sensors for measuring tire pressure and reporting how many times the forklift's forks have been raised/lowered

OBD-II Adapter

The adapter can read various data points from the vehicle's ECU (Electronic Control Unit), including fault codes, engine temperature, oil and fluid levels, and more.

The FLEXGENT

The Flexgent IoT platform, essential for orchestrating Trackgent, serves as a versatile software solution that manages and analyzes data from a network of sensors. Available both as a Docker container for on-premises server installations and as a cloud-based SaaS offering, Flexgent ensures flexibility in deployment with a focus on security and real-time operational visibility through an intuitive dashboard interface.

Discover FLEXGENT

Your Trusted IoT Solution

The platform provides data source integration, extensive processing at the edge, and mechanisms for deployment of data to cloud-based expert systems.The platform provides powerful mechanisms for deployment management, such as device provisioning, environment management and scalability.